diy press brake control

The nicest ready made press brake attachment I have found. First connect the power turn on the key switch on the control panel and then press the pump to start then you can.

Building A 40 Ton Hydraulic Press Brake Machine 21 Steps With Pictures Instructables

IIRC without looking at the chart 14 plate will require with a standard.

. Auto program creation and 2D part simulation 3D graphics available Easy-to-create punches and dies with DXF import feature DXF profile view part file import feature Attaching digital photos to part files to show tooling bend orientation Control Specifications. CNHs Fargo plant also upgraded its backgauge with a powered R-axis which recognizes tooling and eliminates the need to raise the backgauge. Attach and tighten the loose end of the brake cable to the anchor bolt.

Compact solutions without compromise. Here are four ways in which you can make certain you are getting the most out of your existing system. The most basic consideration is ensuring that you know precisely where the most setup time is being spent and how long your bending processes take.

DA-40 series The DA-40s and DA-40Touch series press brake controls. Stretch the wire as much as possible and press the brake pads towards each other slightly. The sheet metal is located between them.

I did things a little out of order but it made sense at the time or maybe not I dont think well in layers. This is the most time consuming step. If a material is 0062 in.

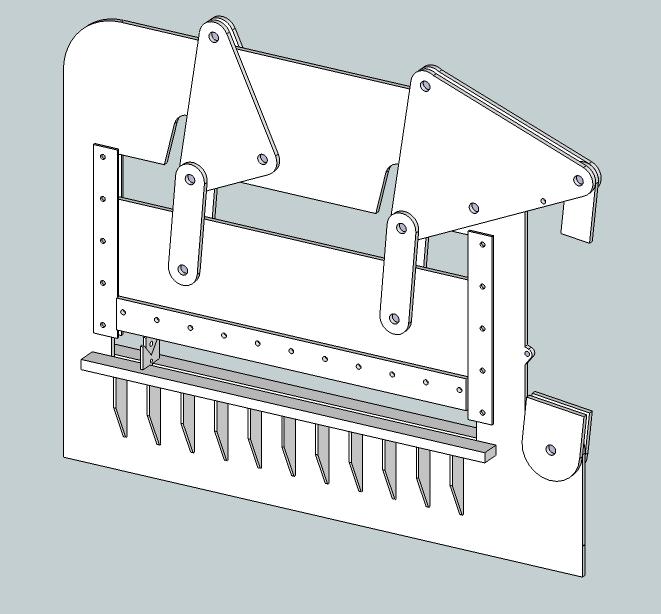

Mechanical Press Brake. DA-50 series The DA-50Touch series press brake controls. These are the parts mostly precut and ready for welding.

April 24 2022 2022 AHRA No Name Nationals at Jeffers Motorsports Park Sikeston MO Car Shows Events May 8 2022 Making a Ford 300 Inline 6 Hybrid with a 53 Liter Chevy LS Cylinder Head Builds and Examples May 7 2022 2022 Roadkill Customs No Name 500 Channel and Vehicle Introductions Car Shows Events May 3 2022 Hot Rod and. 111 Back protection panels or back doors With the machine on and in fast descent open the back door. So heres what it looks like complete.

Here is my homebuilt press brake running Mach3 and dynomotion control. If a material is 0062 in. 20 TON Press Brake DIY Builder Kit Press Brake kit comes unassembled you do the final assembly and weldingDesigned to fit the Harbor Freight 20 ton hydraulic press Item 32879 60603Press brake kit includes an adjustable back stop for accurate and repeatable bends.

8x thickness die opening 20 tons per lineal foot. - Simple fill in the blank boxes or selections for punch die material thickness. Press brake upper die mainly include 90punch 88punch 45punch 30punch 20punch 15punch etc while the lower die includes dual-V die and single-V die with various slot width from 4V to 18V.

An average and commonly used value for the K-factor is 0446. 4-way Die and Holder Dimensions. I cut it open to retrieve the spring.

Pccontrols control retrofits for press brakes. More good reference data from a commercial supplier. Mechanical press brakes are great for accuracy because the machines tonnage comes from its rotation through the bottom dead.

The spring came from a storm door air cylinder that I had laying around. - And then simple fill in the blanks for bend 1 angle length finger ht offset crown. I recommend to people who say.

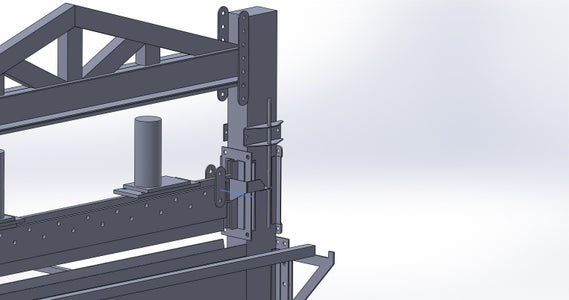

Press brake toolings including L-shape R-shape U-shape Z-shape bending. Control synchronization a height hydraulic cylinders on a press brake. To make the dies I need to machine the stock to a shape suitable to be press dies.

Looking for options on a cnc control retrofit for a press brake on a budget. According to fabricate Q235 mild steel with hydraulic press brake to do a simple introduction. A common press brake control retrofit includes utilizing existing back gauges and replacing the controller with an automec cnc 150 or cnc 300 press brake backgauge control.

We multiply this factor by the material thickness to determine the distance the neutral axis shifted toward the inside radius during bending. Include include Define two steppers and the pins they will use AccelStepper stepperLAccelStepperDRIVER 2 3. Automec Inc Waltham Mass manufactures CNC gauging systems and designs positioning systems with programmable controls that can be retrofitted to press brakes shears cut-off saws and punches.

Extensible modular high-end press brake control solutions. Max Bending Radius deg 110 Max Bending Cap. This is my Bridgeport hogging out the 60 degree wedge shape on the 1 12 x 3 12 piece of steel for the punch side of the brake.

Use the standard 2 die opening min. AccelStepper stepperRAccelStepperDRIVER 6 7. May 14 2013 - For the hobbyist maintenance shop light duty user and the do it yourselfers.

Tooling Notes and Operating Tips. Things I want it to do. A 4-way die would be really slick.

See more ideas about press brake metal working metal working tools. Diy Press Brake Control. Measure your setup operations and average bending times.

So on for each additional bend to build a simple program to bend up. Angle but the back ends of these fingers were flame cut. 112 Side protection panels.

Release the pressure from the brakes and they should retain their position. Turn the machine on and check efficiency of protection devices. Press Brake Tooling Press Brake Dies.

Every press brake control we manufacture ships with our software platform and supports. Ram and backgauge must stop immediately and the reset light must turn on. Your 4 press brake would require 80 tons if you want to run 14 plate and.

The distance between the pads should be roughly the width of the drill handle including the trigger button. If your machine is a mechanical-style press brake with a flywheel and clutch a stand-alone CNC backgauge system can be added to the machine but ram programmability will not be an option see Figure 1. Thick we multiply this thickness by the K-factor to arrive at 0027652 0446 0062.

And then as the punch descends it flips it clear of the block and does its thing. Every press brake control we manufacture ships with our software platform and supports. Sophisticated conventional press brake control solutions.

Easy Diy Guide To Press Brakes Tooling Metal Folding Magnabend Cnccookbook Be A Better Cnc Er

Swag 20 Ton Press Brake Diy Builder Kit Swag Off Road

Easy Diy Guide To Press Brakes Tooling Metal Folding Magnabend Cnccookbook Be A Better Cnc Er

Homemade Cnc Press Brake Homemadetools Net

Home Made Brake Press Plasmaspider Com

Swag Offroad 50 Finger Press Brake Build Plasmaspider Com

Swag 20 Ton Press Brake Heavy Duty Diy Builder Kit Swag Off Road

Thinking Of Building A Press Brake Looking For Opinions Plasmaspider Com

Cnc Hydraulic Press Brake Bp 3305cnc Baileigh Industrial

Building A 40 Ton Hydraulic Press Brake Machine 21 Steps With Pictures Instructables

Building A 40 Ton Hydraulic Press Brake Machine 21 Steps With Pictures Instructables

Yububottles On Twitter Press Brake Metal Bending Tools Metal Bender

Swag 50 Press Brake Diy Builder Kit Swag Off Road

How To Program A Tommy Industrial Cnc Press Brake Delem Da41s Controller Youtube

Single Spindle Electric Press Brake Press Brake Metal Bending Tools Metal Working Tools

Diy Cnc Press Brake In Action Youtube

Diy Press Brake 13 Steps With Pictures Instructables

Building A 40 Ton Hydraulic Press Brake Machine 21 Steps With Pictures Instructables